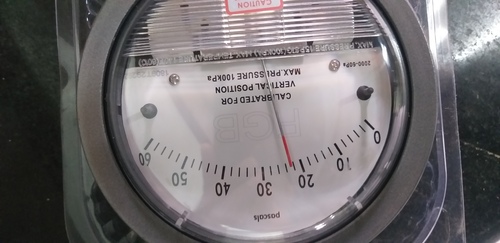

Differential Pressure Gauge

Differential Pressure Gauge Specification

- Bourdon Tube

- Stainless Steel

- Seal Material

- Neoprene Rubber

- Grade

- Industrial

- Sensor Type

- Bourdon Tube

- Thread

- 1/2 Inch BSP

- Outer Size

- 150 mm

- Material

- Stainless Steel

- Dial Material

- Aluminium

- Pointer Material

- Aluminium

- Processing Type

- Forged

- Diameter

- 150 mm

- Glass Size

- 150 mm

- Mount Type

- Bottom Mount

- Scale Range

- 0 to 10 kg/cm

- Accuracy

- 1.6 %

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas, Liquid

- Accessories

- Mounting Bracket

- Case Material

- Die Cast Aluminum

- Operating Temperature

- Up to 60°C

- Overload Protection

- Maximum 130% of FS

- Pressure Connection Type

- Dual Inlet

- Application

- Industrial Process Monitoring

- Movement

- Brass

- Window Material

- Toughened Glass

- Protection Class

- IP65

About Differential Pressure Gauge

Our business enterprise takes the opportunity to commence ourselves as one of the innovative manufacturers and suppliers of Differential Pressure Gauge in the national market. Manufactured using quality grade materials & components sourced from reliable vendors of the market, our gauges are ideal for measuring oxygen pressure, corrosive environment and gaseous media. This Differential Pressure Gauge is tested on various quality parameters, before the final delivery.

Features

- High tolerance level

- Rigid construction

- Smooth finish

Engineered for Industrial Environments

This gauge is crafted from high-quality stainless steel and processed by forging, offering exceptional durability even in challenging conditions. Its powder-coated finish enhances corrosion resistance, making it a reliable choice for long-term industrial use.

User-Friendly Design and Installation

The gauges 150 mm diameter, aluminium dial and pointer, and bottom mount configuration, complete with a mounting bracket, allow for straightforward installation. The large glass face ensures easy readability even from a distance.

Versatile Applications for Gas and Liquid Measurement

Specifically engineered to accurately measure the pressure of both gases and liquids, this gauge supports a scale range up to 10 kg/cm. Its robust construction ensures precision across various industrial processes in India.

FAQs of Differential Pressure Gauge:

Q: How does the Bourdon tube sensor in this differential pressure gauge function?

A: The Bourdon tube sensor within this gauge transforms pressure applied from gas or liquid into mechanical displacement, which is then displayed on the dial, ensuring precise and reliable readings for industrial applications.Q: What materials are used in the construction of this pressure gauge and why are they important?

A: It is built with stainless steel for both the body and Bourdon tube, providing excellent corrosion resistance. The dial and pointer are made from aluminium, and a neoprene rubber seal enhances leak protection, ensuring durability and reliability in harsh environments.Q: When should this differential pressure gauge be used in industrial settings?

A: This gauge should be utilized when accurate measurement of gas or liquid pressure within 0 to 10 kg/cm is essential, such as in process industries, manufacturing plants, or any application demanding high precision and robustness.Q: Where can this differential pressure gauge be installed?

A: With its bottom mount and included mounting bracket, the gauge can be installed on tanks, pipelines, and industrial equipment. The 1/2 Inch BSP thread ensures compatibility with standard industrial fittings.Q: What is the process for installing and maintaining this pressure gauge?

A: Installation involves securely attaching the bottom mount to compatible equipment using the supplied mounting bracket and thread. Regular inspection and occasional cleaning of the glass and dial help maintain optimal performance.Q: How does the accuracy and scale range of this gauge benefit end-users?

A: With a scale range of 0-10 kg/cm and an accuracy of 1.6%, users are assured of precise and dependable pressure readings, which is vital for process control, safety, and efficiency in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Commercial Pressure Gauges Category

Mercury insteel BCPM complete SS

Measure Pressure Of : Other, Liquid and gas

Bourdon Tube : Stainless steel

Processing Type : Other, Manometer or basic pressure testing

Seal Material : Stainless steel

Material : Other, Complete stainless steel

Grade : Industrialgrade

Needle Pressure Gauge (Busting)

Measure Pressure Of : Other, Air, Oil, Water, Gas

Bourdon Tube : Stainless Steel

Processing Type : Other, Precision Engineered

Seal Material : NBR Rubber

Material : Other, Brass & SS

Grade : Industrial

Meghnalic Differential gauge (Manometro)

Measure Pressure Of : Differential pressure in gas or air systems, Other

Bourdon Tube : Not applicable (uses diaphragm sensor)

Processing Type : Mechanical, Other

Seal Material : Rubber gasket

Grade : Industrial grade

Commercial Freon Gauges

Measure Pressure Of : Other, Freon/Refrigerant gases

Bourdon Tube : Yes, corrosion resistant

Processing Type : Other, Precision Machined

Seal Material : Neoprene or NBR

Material : Other, Brass and steel

Grade : Industrial Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS