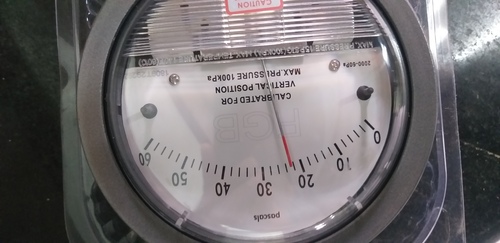

Commercial Freon Gauges

Commercial Freon Gauges Specification

- Grade

- Industrial Grade

- Seal Material

- Neoprene or NBR

- Thread

- 1/4 SAE

- Outer Size

- Approx. 80 mm

- Bourdon Tube

- Yes, corrosion resistant

- Material

- Brass and steel

- Dial Material

- Aluminum, finished

- Pointer Material

- Aluminum

- Processing Type

- Precision Machined

- Diameter

- Approx. 2.5 (63 mm)

- Glass Size

- Full view, standard

- Mount Type

- Bottom or rear mount

- Accuracy

- 1.6% F.S.

- Finishing

- Chrome plated

- Measure Pressure Of

- Freon/Refrigerant gases

- Accessories

- Rubber protective cover, coupling adapter

About Commercial Freon Gauges

Commercial Freon Gauges

We are also dealing in Commercial Freon Gauges which are processed by making use of high grade raw material. We acquire raw material from very authentic vendors of market. These products are highly durable and find application in many industries. These are widely known for their optimum performance and dimensional accuracy. We can also customize these products to fulfill the client needs. These can be availed from us at very reasonable prices as per client specification.

Precision Engineered for Industrial Demands

Designed for tough environments, our commercial freon gauges utilize a precision-machined Bourdon tube mechanism. The combination of high-grade brass, steel, and chrome plating ensures consistent, accurate readings while withstanding corrosive influences typical of refrigerant gases. These features make the gauges highly durable and long-lasting in heavy-duty commercial use.

Adaptable Installation and Comprehensive Accessories

The gauges come with both bottom and rear mounting options, making installation flexible for different equipment layouts. Each unit includes a protective rubber cover to guard against impact and a reliable coupling adapter for seamless connection. The full-view aluminum dial and standard glass window ensure every detail is easily visible and accessible during operation.

FAQs of Commercial Freon Gauges:

Q: How do these commercial freon gauges ensure measurement accuracy?

A: These gauges utilize a precision-machined Bourdon tube mechanism, combined with corrosion-resistant brass and steel components, delivering measurements with an accuracy of 1.6% of full scale. The large, clear aluminum dial further supports precise readings.Q: What types of refrigerant gases can these gauges measure?

A: These freon gauges are engineered to measure the pressure of various refrigerant gases commonly used in air conditioning and refrigeration systems, making them ideal for diverse industrial applications.Q: When is the best time to use this freon gauge for system maintenance?

A: It is best to use the gauge during routine system checks or while servicing refrigeration and air conditioning equipment, as this helps ensure that refrigerant pressures are within safe and optimal ranges.Q: Where can these industrial-grade gauges be installed?

A: These gauges can be mounted at either the bottom or rear of compatible refrigeration or HVAC systems, providing versatility for different installation setups and user preferences.Q: What is the installation process for these gauges?

A: Installation involves attaching the gauge via the standard 1/4 SAE thread using the included coupling adapter. The rubber protective cover is secured to reduce the risk of damage. Options for bottom or rear mounting further simplify the process.Q: How does the design benefit commercial users?

A: The gauges robust build, chrome-plated finish, full-view dial, and protective accessories offer reliability and ease of use, minimizing downtime in demanding commercial environments. Their corrosion resistance also guarantees longevity and performance stability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Commercial Pressure Gauges Category

Vaccume Gauge

Price 265 INR / Piece

Minimum Order Quantity : 10pc Pieces

Pointer Material : Aluminum

Accessories : None

Scale Range : 0 to 1 bar (Vacuum)

Display : Analog

Differential Diaphragm flange type Pressure gauge

Pointer Material : Other, Metal

Accessories : None

Scale Range : 04 kgf/cm

Display : Analog

Differential Piston type Pressure gauge (Hirlekar)

Pointer Material : Other, Aluminum with black finish

Accessories : Standard mounting accessories included

Scale Range : 1 to 25 bar

Display : Analog

Meghnalic Differential gauge (Manometro)

Pointer Material : Other, Black aluminum

Accessories : Standard mounting accessories

Scale Range : 030 psi

Display : Analog

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS